Industries

MAX MOTHES is a leading manufacturer and supplier of high performance connecting technology worldwide.Automotive

Reduction of suppliers and cost reduction through consolidation of manufacturers

Internal production of prototypes

Global sourcing in our strong and reliable partner network

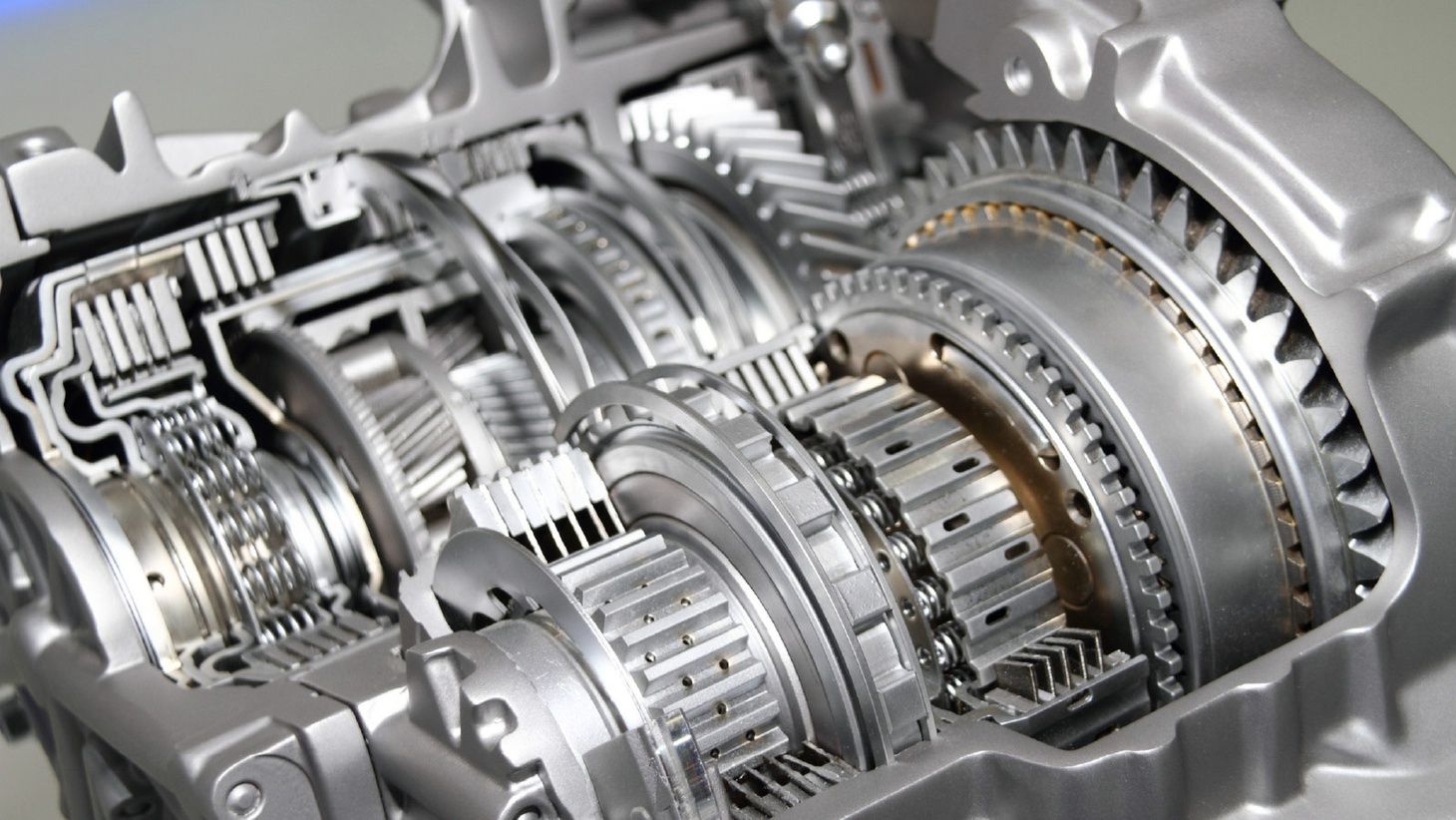

For many, the automotive industry is the fascinating epitome of the collaborative world of production. Sophisticated production systems, the highest specialisation, high volumes and quality standards.

The product is more appealing to many than any other. The automobile is synonymous with individual mobility. The entire industry is on a global basis. These are catch phrases that define the automotive and supplier industries today. The standards here dominate the industry and always represent the pioneering role.

Whether as a supplier of seat structures or interior modules, as a manufacturer of body parts or as a manufacturer of drive components or steering systems - many international automotive suppliers rely on our procurement expertise and our know-how in supply chain management.

Continuous development plays an important role in the automotive industry. The use of lightweight construction and new materials is due to ecological development, high-quality versions of interior trim serve as a distinctive feature of a brand, customer desires place increasing demands on the powertrain and chassis technology. All of these technology drivers are constantly placing higher demands and challenges on joining and connecting technologies.

MAX MOTHES contributes to this with innovative fasteners and delivery concepts. Our customers can count on it globally.

The product is more appealing to many than any other. The automobile is synonymous with individual mobility. The entire industry is on a global basis. These are catch phrases that define the automotive and supplier industries today. The standards here dominate the industry and always represent the pioneering role.

Whether as a supplier of seat structures or interior modules, as a manufacturer of body parts or as a manufacturer of drive components or steering systems - many international automotive suppliers rely on our procurement expertise and our know-how in supply chain management.

Continuous development plays an important role in the automotive industry. The use of lightweight construction and new materials is due to ecological development, high-quality versions of interior trim serve as a distinctive feature of a brand, customer desires place increasing demands on the powertrain and chassis technology. All of these technology drivers are constantly placing higher demands and challenges on joining and connecting technologies.

MAX MOTHES contributes to this with innovative fasteners and delivery concepts. Our customers can count on it globally.

Construction and agriculture

Internal production of prototypes

Remote warehousing

Process and part optimisation through in-house consulting with our application engineers

The way construction and agricultural sectors practice their craft is down-to-earth and solid, and that's also how the machines used for it are built.

Agriculture is becoming more and more important. It is no longer just an industry responsible for serving the needs of the population in terms of food. Agricultural products are increasingly becoming an important source of energy.

Whether extreme heights, high weights or low temperatures - construction machinery must face the extraordinary demands they are built for. Often, they are on duty 24 hours a day, without a break. The construction projects are under great time pressure. These robust devices can only use the highest quality elements. Failure of the machines being used is unthinkable.

Ever-increasing demand, ever-shorter product life cycles and constant changes in the utilised materials call for tremendous flexibility. MAX MOTHES products meet the requirements of the manufacturers and users of the components. We offer the ability to produce products that meet the conditions that prevail under these conditions.

Agriculture is becoming more and more important. It is no longer just an industry responsible for serving the needs of the population in terms of food. Agricultural products are increasingly becoming an important source of energy.

Whether extreme heights, high weights or low temperatures - construction machinery must face the extraordinary demands they are built for. Often, they are on duty 24 hours a day, without a break. The construction projects are under great time pressure. These robust devices can only use the highest quality elements. Failure of the machines being used is unthinkable.

Ever-increasing demand, ever-shorter product life cycles and constant changes in the utilised materials call for tremendous flexibility. MAX MOTHES products meet the requirements of the manufacturers and users of the components. We offer the ability to produce products that meet the conditions that prevail under these conditions.

Mechanical engineering

Parts up to M150 from stock

Process and part optimisation through in-house consulting with our application engineers

Flexible KANBAN systems

A traditional industry such as the German mechanical engineering sector relies on the highest quality and forward-looking innovations.

Worldwide, machines and systems "Made in Germany" are the reference for products of the highest quality and the most precise technological standards. The focus of German mechanical engineering is on innovation and performance. By focusing on continuous improvement in all areas, German machine and system manufacturers are among the world's technology leaders.

MAX MOTHES products meet the high quality standards of this industry. MAX MOTHES is a leader in the manufacture and supply of fasteners that meet the most exacting requirements.

To support the innovative strength of our partners in the mechanical engineering industry, we are always in the front row with our application technology consulting and our internal production capabilities. We support our customers with our know-how when it comes to assembly and connection technology.

We provide support along the entire value chain. The research and development of our customers benefits from our application technology, we support the supply chain with our sourcing and logistics, we accelerate production with our product and processing solutions, and our certified quality management guarantees the highest standards.

Worldwide, machines and systems "Made in Germany" are the reference for products of the highest quality and the most precise technological standards. The focus of German mechanical engineering is on innovation and performance. By focusing on continuous improvement in all areas, German machine and system manufacturers are among the world's technology leaders.

MAX MOTHES products meet the high quality standards of this industry. MAX MOTHES is a leader in the manufacture and supply of fasteners that meet the most exacting requirements.

To support the innovative strength of our partners in the mechanical engineering industry, we are always in the front row with our application technology consulting and our internal production capabilities. We support our customers with our know-how when it comes to assembly and connection technology.

We provide support along the entire value chain. The research and development of our customers benefits from our application technology, we support the supply chain with our sourcing and logistics, we accelerate production with our product and processing solutions, and our certified quality management guarantees the highest standards.

Commercial vehicles

Coatings and strength classes for safe mechanical connections in high-load applications

C-parts management

Efficient screw locking systems

The history of commercial vehicles goes back to the time of the invention of the wheel. It has always been about the accomplishment of transport tasks.

The production of commercial vehicles is influenced by constantly fluctuating demand cycles. The latest state of the art is subject to rapid, steady development. Hardly any commercial vehicle is equipped the same as another. The potential equipment features of commercial vehicles are as diverse as their applications themselves. Today, the workhorses of the global economy are subject to constantly increasing ecological requirements.

To keep pace with this evolution, suppliers and manufacturers in the commercial vehicle industry are equally using the capabilities of MAX MOTHES.

MAX MOTHES offers support along the entire value chain. The research of our customers benefits from the support of our application technology, development is supported by our prototype construction, and we build the unique pieces and samples for tests and pilot series. We support the supply chain with our sourcing and our logistics capabilities. Series production is accelerated by our product and processing solutions, and our certified quality management meets the highest demands.

The production of commercial vehicles is influenced by constantly fluctuating demand cycles. The latest state of the art is subject to rapid, steady development. Hardly any commercial vehicle is equipped the same as another. The potential equipment features of commercial vehicles are as diverse as their applications themselves. Today, the workhorses of the global economy are subject to constantly increasing ecological requirements.

To keep pace with this evolution, suppliers and manufacturers in the commercial vehicle industry are equally using the capabilities of MAX MOTHES.

MAX MOTHES offers support along the entire value chain. The research of our customers benefits from the support of our application technology, development is supported by our prototype construction, and we build the unique pieces and samples for tests and pilot series. We support the supply chain with our sourcing and our logistics capabilities. Series production is accelerated by our product and processing solutions, and our certified quality management meets the highest demands.

Renewable Energy/Power Plants

Availability of large dimensions

Individual kit packaging for direct delivery to the job site

TÜV certified manufacturer of fasteners

We look after our customers in energy technology as comprehensively as we observe at the entire industry. There is hardly a more broad-ranging industry. Energy requirements are increasing every day.

It is a fact that there is a growing hunger for energy due to advancing industrialisation. We see ourselves as responsible for contributing to a sustainable and ecological energy supply. We give it our best!

The range of our customers in energy technology itself is as diverse as their needs for fasteners. Every day we help our customers to produce and commission their state-of-the-art equipment. This ranges from connection and installation technology for the complex controllers of photovoltaic systems, through to materials for the assembly of entire wind turbines.

We support our customers in the selection and supply of the right assembly material, from a blind rivet nut, individual drawing parts, through to the completely commissioned kit, delivered directly to the facility workshop.

Thanks to our contribution, there are no bottlenecks in the production of energy systems, so we contribute a valuable part to our sustainable energy supply.

It is a fact that there is a growing hunger for energy due to advancing industrialisation. We see ourselves as responsible for contributing to a sustainable and ecological energy supply. We give it our best!

The range of our customers in energy technology itself is as diverse as their needs for fasteners. Every day we help our customers to produce and commission their state-of-the-art equipment. This ranges from connection and installation technology for the complex controllers of photovoltaic systems, through to materials for the assembly of entire wind turbines.

We support our customers in the selection and supply of the right assembly material, from a blind rivet nut, individual drawing parts, through to the completely commissioned kit, delivered directly to the facility workshop.

Thanks to our contribution, there are no bottlenecks in the production of energy systems, so we contribute a valuable part to our sustainable energy supply.

Railway technology

Flexible KANBAN systems

Efficient screw locking systems

Coatings and strength classes for safe mechanical connections in high-load applications

The first rail vehicles existed on wooden tracks more than 4,000 years ago. The first driving steam engines in the 18th century laid the foundation for the modern railway.

Today in the 21st century, electrically powered high-tech trains dominate the image of modern rail traffic. The development of high-speed rail traffic is proceeding rapidly. One record is followed by the next.

Hardly any other industry in mechanical engineering faces such challenges as the railway industry. It provides the infrastructure and vehicles for the mobility of the future: ecological and resource-saving.

The railway connects places and people millions of times a day, transporting raw materials and finished products. The railway is the network in which the economy works – both at home and abroad. MAX MOTHES provides the reliable connections for railway technology.

The railway industry needs reliable partners. What is delivered today must be in stock in 10 or 25 years' time. Likewise, it needs quality standards that meet the highest demands - and that for decades.

The railway industry expects innovative solutions for growing quantitative and qualitative mobility demands. From MAX MOTHES, the railway industry can rightly expect that there will be someone who thinks ahead in the field of fasteners.

Today in the 21st century, electrically powered high-tech trains dominate the image of modern rail traffic. The development of high-speed rail traffic is proceeding rapidly. One record is followed by the next.

Hardly any other industry in mechanical engineering faces such challenges as the railway industry. It provides the infrastructure and vehicles for the mobility of the future: ecological and resource-saving.

The railway connects places and people millions of times a day, transporting raw materials and finished products. The railway is the network in which the economy works – both at home and abroad. MAX MOTHES provides the reliable connections for railway technology.

The railway industry needs reliable partners. What is delivered today must be in stock in 10 or 25 years' time. Likewise, it needs quality standards that meet the highest demands - and that for decades.

The railway industry expects innovative solutions for growing quantitative and qualitative mobility demands. From MAX MOTHES, the railway industry can rightly expect that there will be someone who thinks ahead in the field of fasteners.

Deutsch

Deutsch